Industry

Purified Silicon Makes Bigger, Faster Quantum Computers

Pushing out impurities from wafers points toward a million-qubit future.

Purifying silicon for computer chips dates back to the 1950s, and while the industry has arrived at viable purity standards for conventional computer chips, quantum computing demands purer silicon still. So researchers in England have developed ways to eliminate the isotopes that disrupt the delicate qubit states in the silicon. This process could make silicon-based quantum computing more feasible and cost-effective.

The Silicon-28 (28Si) isotope makes up more than 90 percent of natural silicon. But 4.5 percent of raw silicon is 29Si, containing one extra neutron, which effectively gives the isotope a net nuclear spin that can wreak havoc on a silicon qubit’s delicate electron spin states. So to make quantum computers with the maximum coherence times—and therefore computers that can sustain the longest and most complex computations—as much 29Si as possible should be removed or extracted somehow from a silicon qubit substrate.

“Better purity with a method that can be integrated in industrial processes will immediately… [enable] this technology to be scaled to the millions of qubits needed for world-changing applications.” – ANDRE SARAIVA, DIRAQ

“Think of spin as a tiny magnet,” says Paul Smith-Goodson, a principal analyst at the Austin, Tex.-based Moore Insights & Strategy. “Purified silicon-28 has no spin. And a qubit without spin can maintain its quantum state for a longer period of time. An isotope of silicon, such as silicon-29, does have a spin. The spin creates enough magnetic noise to interfere with the qubit’s quantum state and make it collapse.”

The scaling potentials could be big, according to Andre Saraiva, head of solid state theory at the Sydney, Australia-based quantum computing startup Diraq. “Spin qubits in silicon have excellent fidelities, but only after some isotopic purification,” he says. “Better purity with a method that can be integrated in industrial processes will immediately give us better coherence and easier operations, enabling this technology to be scaled to the millions of qubits needed for world-changing applications.”

While some efforts have been made to reduce the presence of 29Si in silicon wafers, they have met with limited success. A team of researchers from the University of Manchester in the UK and the University of Melbourne in Australia have come up with a novel approach to the problem. Rather than try to purify an entire silicon wafer, they chose to reduce the 29Si content of just the regions that would be used by a qubit.

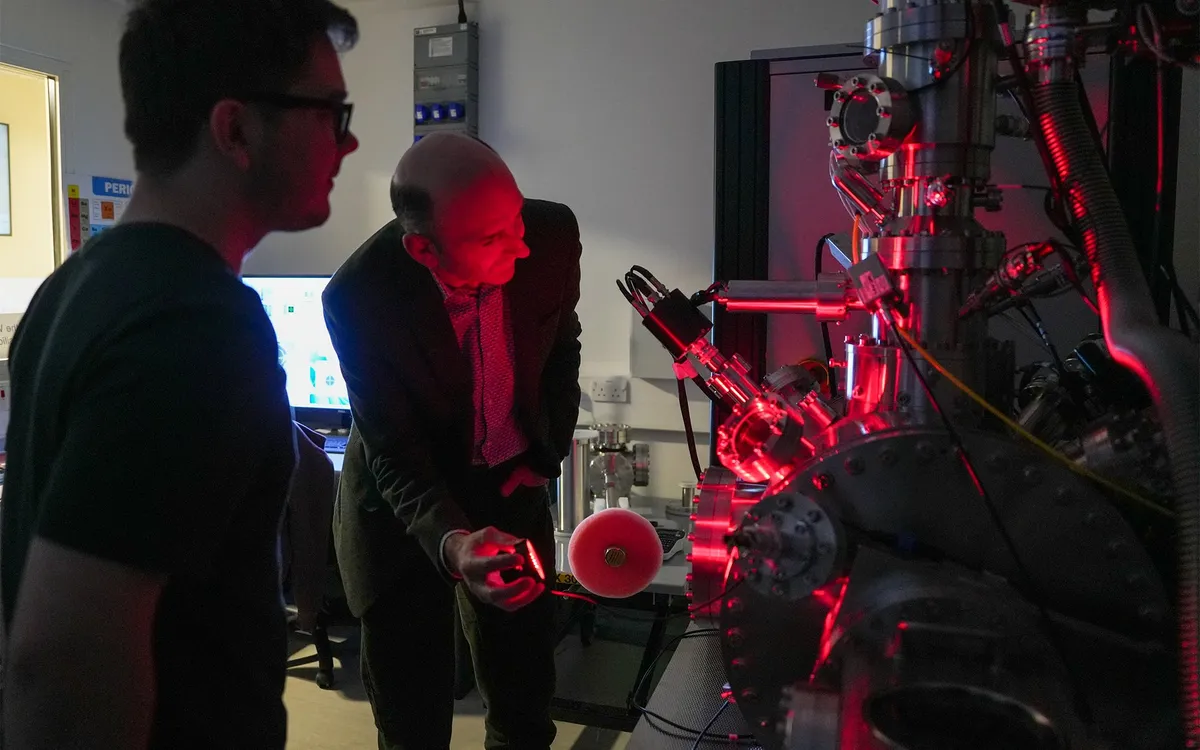

A focused ion beam of silicon-28 strikes a natural silicon wafer—forcing out the unwanted silicon-29 isotope—in a new purification technology that could be used to make a silicon wafer more suitable for housing delicate spin qubits. NATURE COMMUNICATIONS MATERIALS

To accomplish this, they placed the wafer in a vacuum and bombarded the target area with a focused ion beam of 28Si atoms. When the beam strikes the wafer, it displaces the existing silicon atoms, replacing them with just the 28Si isotope. They used a device that produced a beam with about a 500 nanometer diameter. This beam was raster scanned across a square target area 22 nanometers on a side. That, the researchers say, is an area sufficient to house a 12,000 qubit array. The wafer then goes through a two-step annealing process to return the irradiated material to a crystalline phase.

The researchers managed to produce samples with fewer than 3 parts per million of 29Si—some 1/10,000 less 29Si impurities than what exists in natural silicon.

By treating only the target areas, the process is more efficient and scalable than other processes that attempt to physically separate the isotopes, such as by centrifuge. An additional advantage of the ion beam enrichment process is that it does not introduce other contaminants into the silicon wafer. Other procedures can introduce additional carbon and oxygen during the enrichment process.

Richard Curry, professor of advanced electronic materials at the University of Manchester, says the research team wanted to develop a technology that “was scalable and compatible with standard silicon device processing,” he says. “This allows for its adoption in the future manufacturing of silicon-based quantum technologies.”